With the development of more sophisticated pumps capable of producing ever higher vacuum, the uses to which vacuums are being put have mushroomed, and now encompass a wide range from scientific research to food technology to semiconductor fabrication.

R&D is a significant “client” for vacuum technology, of which the most exciting involves the study of particle physics, conducted in particle accelerators (or colliders). These machines use huge electromagnetic fields to accelerate protons to velocities approaching the speed of light, focused into a fine beam, and then monitored from their collision with other particles.

The world’s most powerful particle accelerator, the Large Hadron Collider, is run by Conseil Européen pour la Recherche Nucléaire (CERN), and occurs within a series of tunnels that cross the border of France and Switzerland. High-speed beams of protons are channelled into a detection chamber where they collide with a proton “cloud” contained within an ultra-high vacuum. The resulting “exotic matter” that spills out of such collisions are short-lived but, nevertheless, the decay products can reveal the sub-atomic building blocks that control almost everything in our Universe…but none of this would be possible without the ability to create (and control) an ultra-high vacuum.

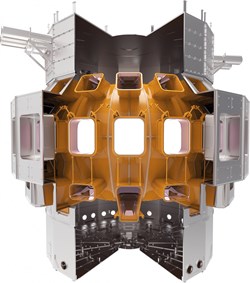

Nuclear fusion occurs when two atoms combine to form a new atom, with the spare neutron that is “left over” providing energy that can be harvested for re-use. To get such atoms to combine (and release their spare energy) they need to be fired into plasma where temperatures of approximately 150 million°C overcome ion-repulsion and force them together. However, the machinery and knowledge associated with vacuum technology have only recently become available to elevate fusion to possible viability.

Source: ITER

Space Research

Vacuum science has been integral to major scientific advancements, including those associated with space research (and in particular, the detection of gravitational waves and black holes), by employing ultra high vacuum (UHV) levels.

Gravitational waves are ripples in space-time that are caused by violent processes such as exploding stars, collisions between neutron stars or the merging of black holes.

In order for gravitational waves to be detected in an interferometer (consisting of light storage arms), UHV conditions are needed. However, to operate effectively whilst maintaining direction, gravitational wave detectors must maintain ultra-high vacuum conditions (because sound waves cannot exist within a vacuum).

Click here to read our blog on Vacuum Technology for Space Simulation Chambers.

Vacuum pumps are therefore an essential part of gravitational wave detection systems. As pressure ranges down to 10-09 mbar must be obtained, the most common vacuum pumps employed are magnetic turbomolecular, ion getter, cryo and “dry” fore-vacuum pumps.

The first image of black holes initiated the notion of them as a volume of space where their gravity is so extreme that neither fast moving particles nor light can escape. However, as black holes do not emit visible light, astronomers were unable to capture clear pictures of them. With advancements in vacuum technology, this is no longer the case.

From a quantum perspective, the existence of black holes suggests that these “space vacuums” are not completely empty, and that in fact a black hole’s strong gravitational field fluctuates. With recent observations, as well as the progression of vacuum technology seen in telescopes and gravitational wave detectors, the nature of black holes will enable researchers to make new predictions and discoveries about the Universe and its origins.

Analytical Instruments

One of the most ubiquitous uses of vacuum pumps in the laboratory is in mass-spectrometry (MS). The pumps associated with such MS units are at the vanguard of the high-tech vacuum industry in terms of automation, control, compactness, resolution, efficiency, quiet operation, low-maintenance and cost effectiveness.

MS enables the near-immediate identification and measurement of thousands of types of molecules (e.g. metabolites, lipids, proteins, small molecules etc.), whilst also providing a detailed picture of how cells and tissues respond to drug treatment, but without the use of expensive reagents.

Furthermore, by combining MS with other technologies, it has been possible to make significant advances in a number of important medical fields including: the characterisation of advanced cell models; biomarker identification; drug distribution/tissue penetration; isotope tracing; as well as observing spatial changes in drug and metabolite distribution. Such MS developments have helped to unravel the mysteries of effective drug treatments and bio-medical science in general…and yet they all rely upon the humble vacuum pump.

A residual gas analyser (RGA) is a small MS which can monitor vacuum quality by detecting (and measuring) minute traces of impurities in a low-pressure gaseous environment. RGAs effectively identify the chemical components of the gas within a vacuum, by ionising the various molecules present to create ions before determining their mass-to-charge ratio.

RGAs are employed in vacuums where residual gas species need to be identified and where process conditions need to be monitored or controlled. RGAs play an important part in numerous fabricating processes, such as coating processes, vacuum furnaces and basic R&D.

KATRIN (Karlsruhe Tritium Neutrino Experiment) is a programme to measure the mass of the electron anti-neutrino, with sub-eV precision—in order to answer one of neutrino physics’ most critical questions: “What is the absolute mass of neutrinos, and why are they so important?”

Source: Karlsruhe/KIT Katrin

Neutrinos are probably the most fascinating species of elementary particles, and indeed are referred to as the “ghost particles of the Universe”. Although neutrinos are the lightest particles in our Universe, on a grander scale they act as “cosmic architects”. In many ways one can think of neutrinos as the “DNA of matter”.

Since neutrinos have no electrical charge, their energy is measured against the shape of the electron spectrum generated by a tritium-β-decay, with measurements taken using an electrostatic spectrometer. Due to the necessity for high sensitivity, these spectrometer units have to operate in an absolute ultra-high vacuum (UHV) of nearly 10-11 mbar to avoid “false” readings generated by residual atoms that have been ionised by cosmic radiation. KATRIN’s 200-ton spectrometer with a volumeof 1,230 m3, is one of the world’s largest UHV vessel.

Another instrument used for vacuum measurement is the mercury barometer. Learn about the figure behind this here.

Wherever and whenever a vacuum needs to be created, it is essential to ensure its integrity (i.e. the “tightness” of the system), if not then time is squandered, and effort is pointlessly spent trying to create a vacuum in an “open system” which could never support a vacuum in the first place.

The only credible method for vacuum leak detection smaller than 1×10-6 mbar*l/s is with a helium leak detector of which there are four methods: the integral (sample under pressure) method requires the chamber to be placed inside a gas-proof unit–not always a possibility–and either internal or externally pressurised. Whereas in the local (sample under vacuum) method the chamber is either internally pressurised with helium or internally evacuated, with helium generously sprayed onto the surface of the chamber at likely leak prone points. In all four tests, helium enters the leak detector via possible leak points and is passed to the spectrometer for analysing.

Multiple Applications

Vacuum insulated glazing is an emerging technology in the field of energy efficient buildings, aimed at meeting the severe thermal performance requirements of net-zero energy windows. This is achieved by creating (and maintaining) a vacuum between panes of glass, (so that no gas/air enters this void). This maximises thermal efficiency and sound insulation.

Triple-vacuum insulated glazing (TVIG) has the ability to reduce thermal heat flow between the warm and cold-side of a window, i.e. it provides high thermal insulation (or lower U-values) by approximately 88.2% when compared with triple-air filled glazing. TVIG is constructed with three sheets of 4mm-thick glass, with an evacuated cavity of less than 10-3 mbar vacuum.

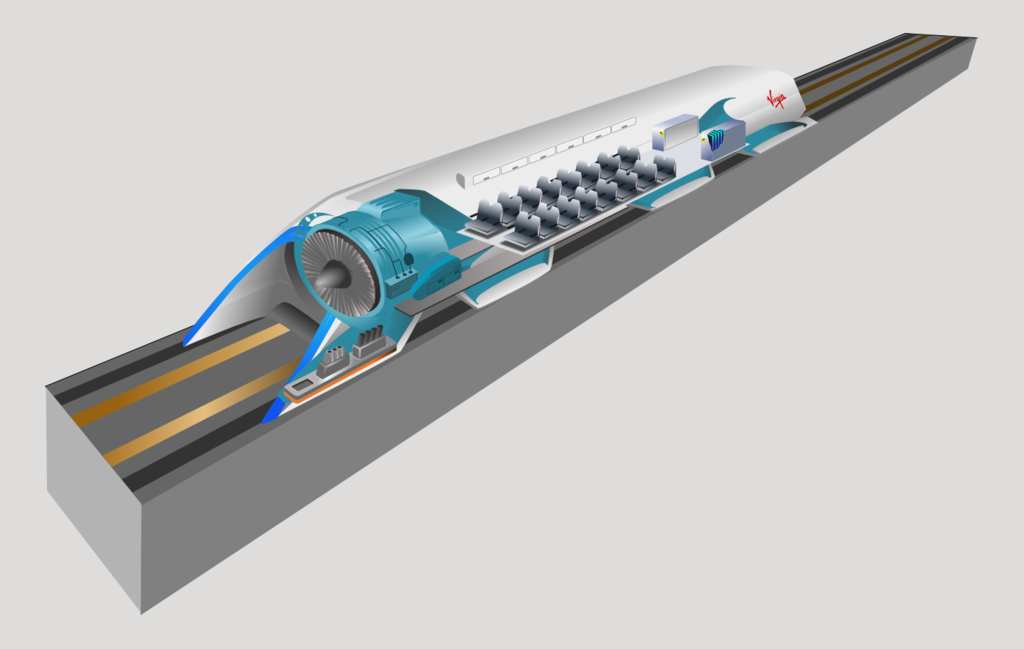

Throughout mankind’s recent evolution, the desire to perfect transportation has galvanised scientists and engineers towards change and innovate, such as that provided by the “Hyperloop”.

Simply put, the Hyperloop utilises a vacuum in a sealed-tube along which a passenger capsule travels. Using a vacuum significantly reduces air resistance. When this is coupled with low-friction propulsion and levitation technologies (based on air cushion or magnetic levitation) within a closed system, it sends the capsule shooting “bullet-like along the rifle barrel” of the tube at ultra-high speeds, with the absolute minimum of effort.

A recent paper outlined that, in this way, the Hyperloop scheme could propel passengers at 1,200km/h along a 560km route in only 35 minutes (i.e. considerably faster than trains, and less environmentally damaging than aircraft).

However, an essential part of the whole Hyperloop scheme is without doubt, creating a vacuum of 1 mbar which although “not rocket science”, needs to be “scaled-up”. For example, the vacuum system of a 200km length and a 4m-diameter tube (i.e. 2.5 million m3), requires considerable expertise and understanding of vacuum physics, material knowledge, as well as vacuum simulation.

Fresh food products rapidly deteriorate unless some way can be found to preserve them. There are two different processes employing food packaging vacuums. In vacuum microwave drying (VMD), products are heated by microwave to between 35 and 60oC whilst the vacuum pump keeps the pressure around 10 mbar. The water content then evaporates. In freeze drying (FD), the products are cooled to between -20 and -40oC and the water sublimates from the solid phase at pressures below 0.1 and 1 mbar. This process is also used for freeze drying coffee and pharmaceutical products.

Because vacuum food packing removes the air from the package before sealing it, their “shelf life” is significantly increased as almost all oxygen is removed, which restricts the growth of bacteria and fungi. Using vacuum packing, the lifetime of packed beef is about 3 weeks, while for pork it’s approximately 10 days.

Vacuum technology is used extensively in numerous medical applications: the manufacture of prosthetics, the coating of medical devices, magnetic resonance imaging, proton therapy and cyclotrons.

Vacuum equipment is used in two (but essentially different) parts of the “Kroll” titanium manufacturing process. Titanium is stronger and more durable than steel but is 45% lighter. Furthermore, titanium is non-ferromagnetic, which allows patients with artificial body parts (such as orthopaedic pins, rods, plates, and joints) to be safely scanned by MRIs and NMRIs. Most notably, titanium is one of the only metals that will effectively bond with human bone and tissue.

While X-rays are mainly used to examine bones, magnetic resonance imaging, (MRI) is used to look at soft tissues, such as organs, ligaments, the circulatory system, and spinal cord. Most MRI scanners employ large superconducting magnets cooled (to near absolute zero) by cryogenic fluids. Once in the superconducting state, current can flow through the (zero resistance) magnet coils indefinitely without the need for a power source. The magnet is housed in a cryostat, which is a vessel built inside another vessel. Between the inner and outer vessels, a vacuum plays a critical part in restricting heat from entering the cryogenic fluid.

Proton therapy is the most advanced form of radiation therapy today, but unlike traditional radiation therapy, it directly treats cancerous tissue without harming surrounding healthy tissue and organs. Proton therapy’s precise delivery of radiation is due to the way in which protons release their energy as they travel through the body. However, to create the necessary energy and velocity for treatment, protons are sent through a vacuum tube into a super high-speed accelerator known as a cyclotron, that speeds up the protons. After exiting the cyclotron, the protons continue (in the vacuum tube) through more magnet-rings that steer and focus the beam. Similar to MRI, many of the cyclotron magnets are superconducting and housed in a cryostat, with similar cooling principles using liquid helium and insulated by vacuum.

Vacuum coating is used to deposit layers of material (atom-by-atom or molecule-by-molecule) onto a solid surface within a vacuum. The deposited layers can range from a thickness of one atom, up to millimetres. Multiple layers of different materials can be employed, for example, to form optical coatings. In this way, many medical devices placed inside the human body (i.e. pacemakers, stents, epidural probes, defibrillators etc.) are surrounded with special film coatings to protect the body from the leaching of metals or plastics and protect the device from body fluids.

One of the most widely used materials to coat these devices is Parylene (which provides an ultra-thin, pinhole-free barrier) and is deposited on the medical devices through a vacuum deposition process. Parylene coatings are applied to medical devices inside a vacuum chamber using vapour-deposition polymerisation (VDP). The Parylene is deposited on the device building up one monolayer at a time, so it uniformly coats the entire device, penetrating even the device’s smallest cracks and crevices.

Ultra-centrifuges are super-powered centrifuges that rotate at speeds faster than 200,000 rpm (creating up to 100,000 g) and can separate out extremely tiny particles in solution. However, as they spin so quickly, the rotors reach extremely high temperatures causing convection currents that disrupts solid: liquid separation. To avoid this, rotors in ultra-centrifuges are housed within a vacuum. The elimination of air resistance allows the rotors to be spun at very high-speeds, aids separation, as well as reducing the power input needed.

Whether you work in the R&D field, with analytical instruments, or using industrial and process vacuum – you will need a vacuum system that ensures safe operation, is highly reliable and built-for-purpose to meet your operating requirements.